Build Series - Brute Force

The Brute Force series is the perfect balance of being strong while staying lightweight. The series is available for all Tripping Canoes and Adirondack Pack Canoes. Marathon Racing Canoes are available in a version of Brute Force called Kevlar Club Race.

We’re often asked “What is your toughest canoe?” and the answer is “Epoxy Pro Series, Brute Force.” The Brute Force series hits all targets for most paddlers: tough, light, visually attractive, and available with virtually every canoe we produce.

Although the dominant reenforcement is visible on the exterior, it is laminated behind a transparent outer strength layer. This technique commonly called ‘skin coating’ is lighter and requires less maintenance over the course of ownership than a gelcoat canoe. Unlike a gelcoat, which is inherently thick and prone to damage upon impact, the Epoxy Pro Series Brute Force is responsively flexible at impact and has an exterior that is composed of strength rather than filler.

Some features of the Brute Force series include industry standard aluminum gunwales with ABS end caps. These basic components are thought through to ensure they meet the goals of ultimate strength at the lightest weight possible. Most of the features of the Brute Force series are unique and strategically developed to create the best results in the lightweight canoe category. The Brute Force series is comprised of performance reinforcements handcrafted with techniques that aren’t quick or easy. The result is an attractive, long lasting hull with no undesirable features—a true performance canoe in the lightweight category.

With most 16′ canoe options coming in at the 40-45lbs range, our Brute Force series is redefining the lightweight canoe category. The Brute Force series is suited for any canoeist interested in a lightweight canoe for tripping. Rental outfitters love the different lamination options for their fleets, which are ideal for extended use while requiring little maintenance.

The laminations in our Brute Force series offer the most rugged and durable options for a lightweight canoe. The series is specifically developed with its weight in mind, to create a tough canoe suited for portage tripping; however it is not a substitute for much heavier, indestructible materials. The Brute Force series is able to take many impacts with little negative results, but keep in mind it represents a durable lightweight performance canoe rather than an indestructible rock basher.

Epoxy Resin is used for bonding reinforcement, which is the most formidable resin in composite construction. Epoxy is a heat cured product that retains a level of inherent flexibility while holding a rigid shape. Epoxy is regarded as the pinnacle of resin systems used in production of marine, aircraft and space programs. While Epoxy Resin is a premium component that is challenging to use correctly, it’s the secret behind our Epoxy Pro Series canoes that differentiates our boats in the canoe industry. Using Epoxy Resin adds a significant amount of time and effort to manufacturing and is used only on high end products. It is specifically developed to maximize longevity and maintain performance for the life of the product.

The transparent outer skin in our Brute Force series is more oz per square yard than any competitor we know. The hulls are cored for strength with closed cell foam and the side walls are reenforced with thick targeted kevlar ribs. The attractive aluminum gunwales and a bracketing system for cross members keep the boat rigid and durable for efficient paddling.

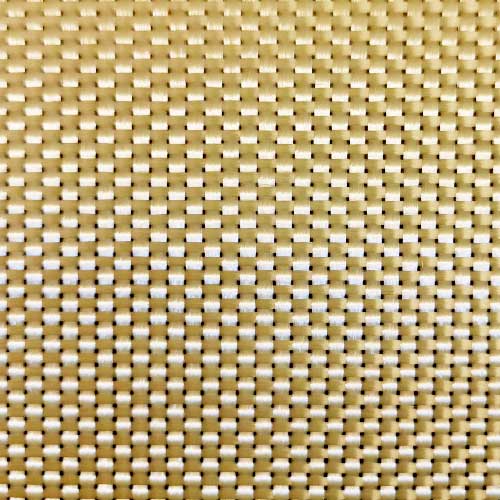

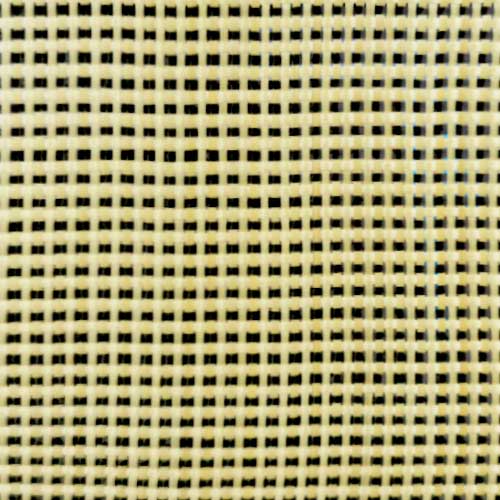

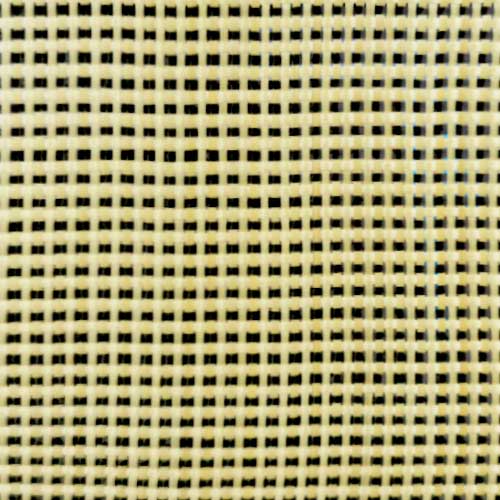

Our Brute Force series is offered in a variety of technical fabrics, including Flax, Kevlar, Innegra Basalt, Carbon Kevlar and Carbon Innegra. These fabrics laminate around a rigid reinforcement system, matched with epoxy resin to construct the hull.

The Brute Force series begins with a substantial outer skin of fibreglass which is easy to repair and takes a fair amount of wear before needing repair. Behind the fibreglass is your choice of technical fabric: Flax, Kevlar, Carbon Kevlar, Co-mingle Innegra Basalt, Innegra Basalt or Carbon Innegra. The same choice of technical fabric or a complimentary option is used for the inside of the canoe. The visual appearance of our Brute Force series is determined by the technical fabric that they are constructed from.

Both the inside and the outside of the canoe are coated with a very thin sealing product which is UV stable and easy to clean and maintain.

Standard finishes on our Brute Force series include: aluminum gunwales in your choice of black or silver anodized finish, varnished ash deep dish yoke, handles, thwart, webbed contoured seats, ABS end decks, flotation chambers, and stainless-steel hardware. Optional finishes for the Brute Force series include: bow sliding seat, Kevlar skid plates, black stained ash or cherry wood, float tank hatches, and kneeling thwart.

There are two options for colour customizing your Brute Force Canoe:

Option 1, Two-tone: A two-tone colour finish is available with a coloured gelcoat on the bottom of the hull with the top remaining clear in technical fabric.

Option 2, Woven Colour: Kevlar and Carbon Kevlar canoes are available in full coverage red, blue, or green woven colour options. Please see our Buying Guide for more information.

Available Colours

Kevlar

Carbon Kevlar

Co-Mingle Innegra Basalt

Innegra Basalt

Carbon Innegra

Flax

Woven Red

Woven Blue

Woven Green