Build Series - Pro Lite

The Pro Lite series is our lightest series to breeze through those long portages. The series is available for all Tripping Canoes and Adirondack Pack Canoes. Marathon Racing Canoes are available in a version of Pro Lite called Carbon Race or Carbon Ultralight.

Epoxy Pro Series Pro Lite is our most advanced construction system yet, embodying what it means to create an ultralight canoe that remains durable against wear, tear, and mishaps. Its aesthetics stop observers in their tracks, while the design is professionally constructed for both performance and efficiency. The Pro Lite series combines advanced composite construction techniques with the modern requirements of paddlers, pursuing lighter and stronger equipment than ever available. The Pro Lite series was born from extensive research studying every feature we could find from current and historic canoe manufacturers, bringing everything together to create the ultimate build.

The Pro Lite series is our most innovative series yet with many complex features that go beyond an ordinary canoe build. Our carbon wrapped Integral Composite Gunwale (ICG) complements the rib reinforcements and closed cell foam used in the hull. An Epoxy Resin system is used in this complex build matrix to achieve maximum strength, while a unique method of skin coating is used to create a UV resistant, repairable, ultra thin, and ultra light coating for the boat. An ultra light aluminum trim over the carbon wrapped gunwale offers unmatched longevity while reducing the total canoe weight by approximately 5 to 7 lbs. This weight reduction allows us to put additional weight in other places for strategic reinforcements, so there’s no compromise in durability.

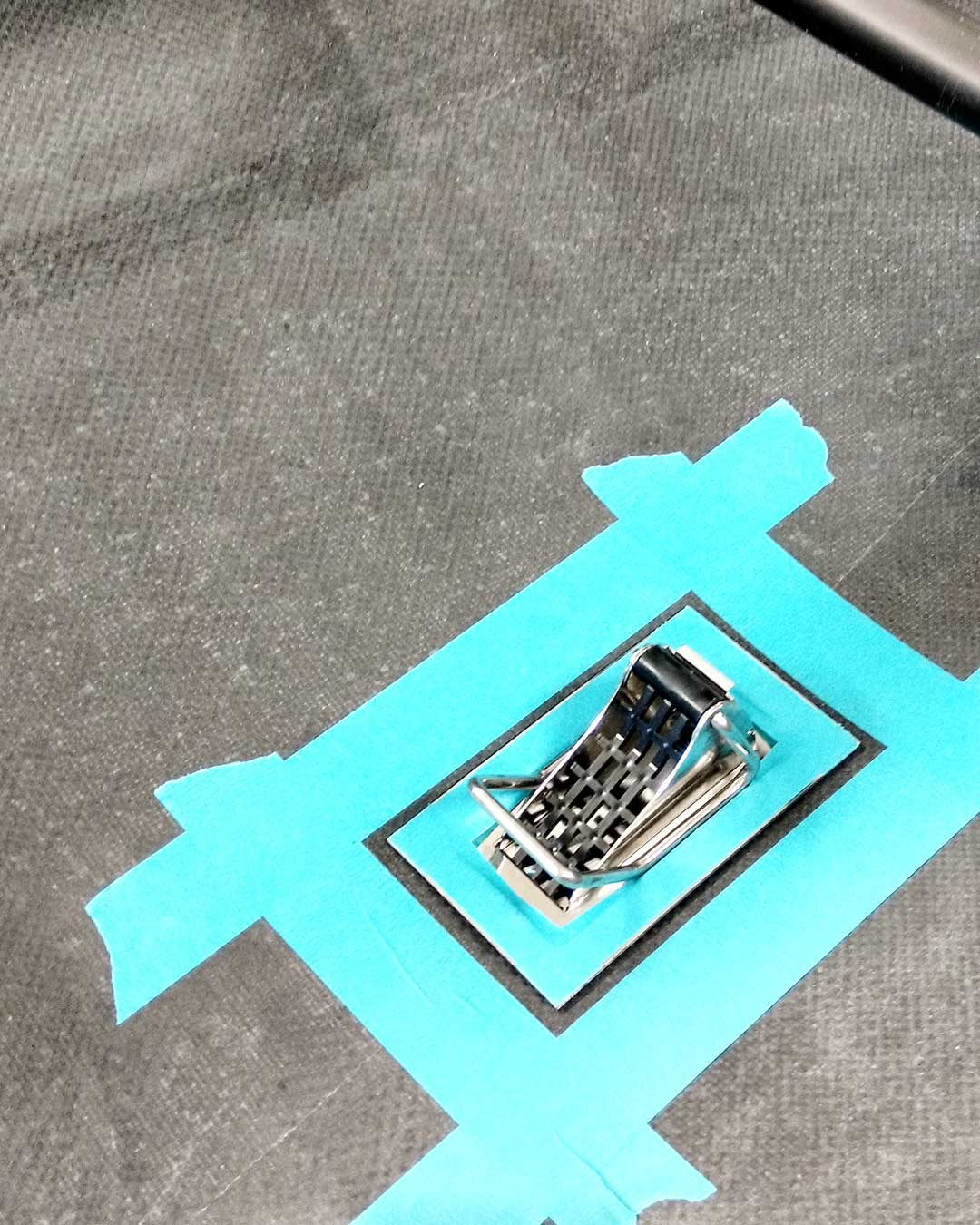

Our rib system keeps the canoe rigid enough to perform, while creating just enough flex between ribs to absorb impact. It is subtle, but even the area surrounding the seat mount includes a cross rib for strength to support a seat bracket, which is both adhered and riveted to the hull. When the seat is fastened to this mount there is no movement or sway and the strength in the hull is increased similarly to a truss construction technique.

The Epoxy Pro Series Pro Lite is suited for canoeists who want the lightest boats available on the market. The series is under 40lbs in almost all canoe models, with most 16′ options ranging between 33 to 37lbs.

There are now thousands of Pro Lite canoes used throughout North America, purchased both by individual owners as well as rental outfitters. Outfitters love the Pro Lite series due to the very little maintenance required over years of use.

The Pro Lite series has redefined what it means to paddle a lightweight, capable canoe in the backcountry. There is little to no limitation to who can use a Pro Lite. Suited for a variety of tripping uses, if it can’t be done in a Pro Lite, it probably can’t be done at all.

The Pro Lite series is one of the lightest canoes available worldwide and remarkably it is still one of the toughest, durable, and most rugged canoes. It is developed specifically as an ultralight portage capable tripping canoe, but it is not meant to replace heavier indestructible materials. A Pro Lite canoe can take many impacts with little negative results but keep in mind it represents optimal performance rather than an indestructible rock basher.

Epoxy Resin is used for bonding reinforcement, which is the most formidable resin in composite construction. Epoxy is a heat cured product that retains a level of inherent flexibility while holding a rigid shape. Epoxy is regarded as the pinnacle of resin systems used in production of marine, aircraft and space programs. While Epoxy Resin is a premium component that is challenging to use correctly, it’s the secret behind our Epoxy Pro Series canoes that differentiates our boats in the canoe industry. Using Epoxy Resin adds a significant amount of time and effort to manufacturing and is used only on high end products. It is specifically developed to maximize longevity and maintain performance for the life of the product.

The transparent outer skin in our Pro Lite series is made from fibreglass, which is easily maintained and easily refinished if required. The hulls are cored for strength with closed cell foam and the side walls are reenforced with the same closed cell foam ribs, formed to shape.

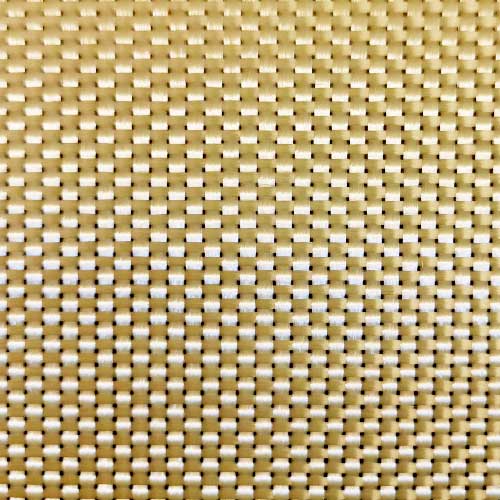

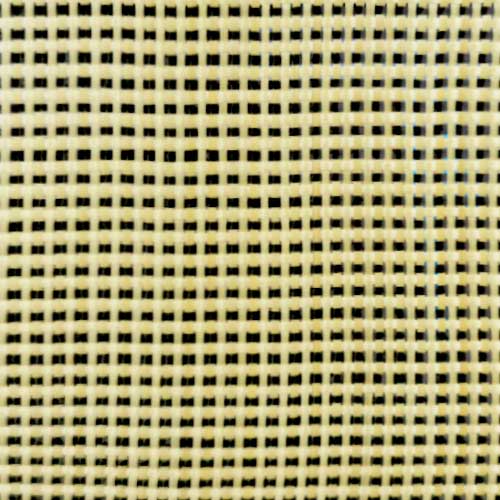

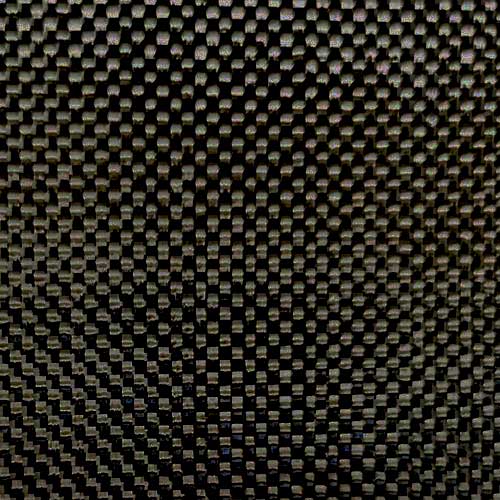

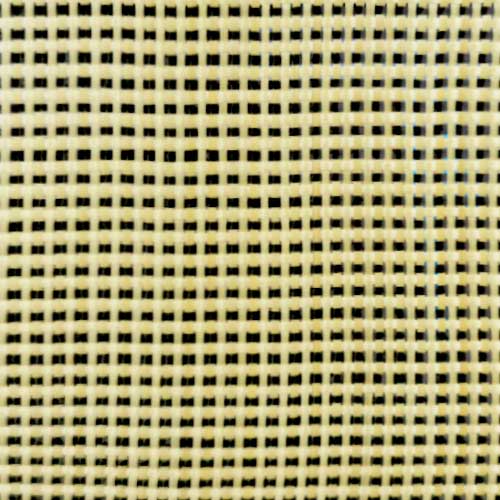

Our Pro Lite series is offered in a variety of technical fabrics, including Flax, Kevlar, Innegra Basalt, co-mingle Innegra Basalt, Carbon Kevlar, Carbon Innegra or Carbon Fiber. These fabrics laminate around a rigid reinforcement system, matched with epoxy resin to construct the hull.

The Pro Lite series begins with a substantial outer skin of fibreglass which is easy to repair and takes a fair amount of wear before needing repair. Behind the fibreglass is your choice of technical fabric: Flax, Kevlar, Carbon Kevlar, Carbon Fiber, Co-mingle Innegra Basalt, Innegra Basalt or Carbon Innegra. The same choice of technical fabric or a complimentary option is used for the inside of the canoe. The visual appearance of our Pro Lite series is determined by the technical fabric that they are constructed from.

Both the inside and the outside of the canoe are coated with a very thin sealing product which is UV stable and easy to clean and maintain.

Standard finishes on our Pro Lite series include: integral composite gunwale (ICG) in your choice of black or silver perimeter trim, anodized finish, varnished ash deep dish yoke, handles, thwart, webbed contoured seats, ABS end decks, flotation chambers, and stainless-steel hardware. Optional finishes for the Pro Lite series include: bow sliding seat, Kevlar skid plates, black stained ash or cherry wood, float tank hatches, and kneeling thwart.

There are two options for colour customizing your Pro Lite Canoe:

Option 1, Two-tone: A two-tone colour finish is available with a coloured gelcoat on the bottom of the hull with the top remaining clear in technical fabric.

Option 2, Woven Colour: Kevlar and Carbon Kevlar canoes are available in full coverage red, blue, or green woven colour options. Please see our Buying Guide for more information.

Available Colours

Kevlar

Carbon Kevlar

Co-Mingle Innegra Basalt

Innegra Basalt

Carbon Innegra

Carbon Fiber

Flax

Woven Red

Woven Blue

Woven Green